Extrusion control

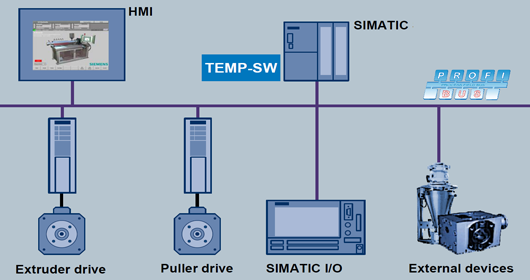

Our Extrusion Control System provides integrated line control for all extrusion applications, including pipe, profile, tubing, sheet, reclaim, compounding, fiber, and film. PC&E engineers design a Control Systems to your specifications, including end-users’ process requirements and preferred supplier hardware.HMI can range from standard CE-based four-color touch panel to an industrial-strength PC running Windows 8.1 SCADA software packages (C#, C++, Visual Basic,GE IFix, Wonderware, Citect).

These robust systems are built to withstand factory environment High temperatures, dust, humidity, vibration, and other plant conditions.The Control System can be retrofitted for ALL makes and models of extruders. It also can be provided with PC&E Extruder product line. Features include:PLC-based extrusion control system utilizing off-the-shelf components •Utilizes all major platforms from automation manufacturers: Allen Bradley, Siemens, Barber-Colman, Beckhoff, Vario, BR, and more.

HMI, PLC, and PC, can be used to control all required line functions, plus provide an interface to all process-related ancillary equipment.

Provides alarm annunciation, historical trending, unlimited recipe storage, reporting, and multi-level security access.

Easy-to-use controls come in English or optional Spanish language. The system monitors or controls all temperatures, speeds, amperages, and pressures of the extrusion system, including all downstream and upstream equipment.

All PC&E systems have full industry-standard Ethernet/IP capabilities or Profibus field bus protocols for complete, integrated line control.

This seamless integration of upstream and downstream equipment-data monitoring makes quality control and process analysis far more efficient with data requirements clearly identified.

The system provides real-time run data, allowing for operator line control and supervisory access to all production/process parameters. Time and date-stamped data records all line functions for shift reports, daily/ weekly analysis and more.