Integrated Packaging Systems

Project Description

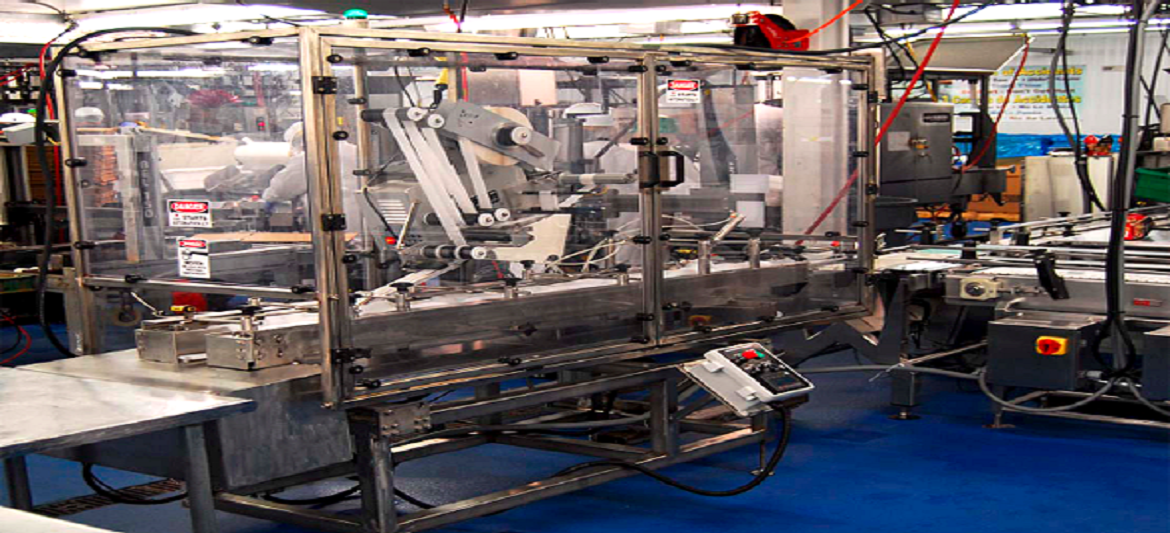

After a negative experience with an OEM, the client looked to EPIC to upgrade their integrated packaging systems, which included pail filling machines and a palletizer

Project Starting Date 12/01/2016

Project Ended Date 2/17/2017

Category Research

AN EPIC INTEGRATED PACKAGING SYSTEMS SOLUTION

Front- End Engineering

EPIC first completed its front-end engineering approach to assure the most efficient process and accurate quotation. After reviewing the state of the current packaging/filling line with the client, EPIC’s engineers completed a line evaluation and created an implementation plan that included the following elements:

-

- Reprogramming of the original equipment in the pail filling line

- Specifications for mass micro-flow meters for increased efficiency

- An infeed line which included a capper, crimper and a lift assist at the end of the line

- Control system integration to create a semi-automatic line

EPIC Systems recommended an efficient option for advanced line automation and machine vision inspection for QA checks.

Work Scope

- Custom specified and modified palletizer

- Semi-automatic, integrated control system

- Custom infeed line, capper, crimper and lift assist

- Complete and correct filler reprogramming

- Accurate mass micro-flow meters