Barrel Line PLC Programming

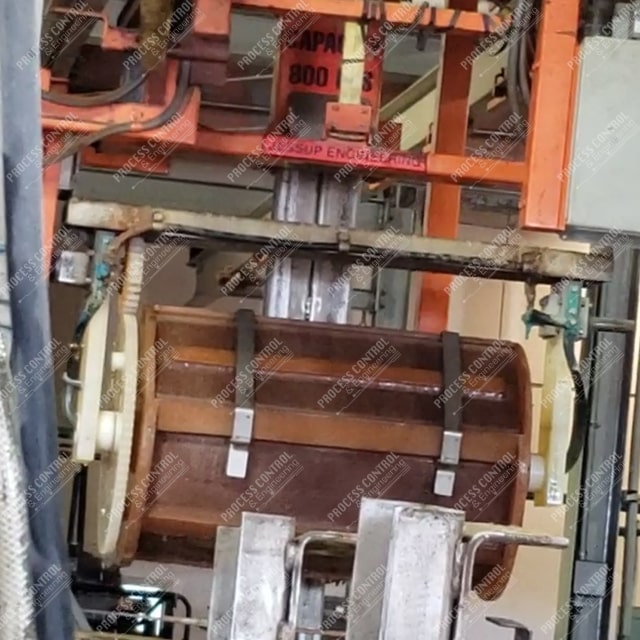

Problem

The customer had a plating machine; the plating process was carried out manually, which represented a lower production efficiency, since the plating process was long and this led the operators to take a long time in each cycle.

Solution

PC&E designed an algorithm with the capacity to solve the needs that the client was looking for, such as:

- Improvements in production time

- Increase in product quality

- Ergonomics in the plating process

The machine has a sophisticated automation system, which is able to know and anticipate errors and failures in the system, preventing accidents and loss of raw material. This process has an advanced logic due to the logistics involved in the plating process.

If the customer wishes, the control system is capable of modifying the plating process, depending on the requested needs, since it has the capacity to store up to 4 different types of recipes, being these recipes fully configurable to change the process as required.

Duration

About 10 weeks

Services Provided

- PLC & HMI Programming

- Drives AC/DC & Motion

- Electrical Design & Schematics

Technology Used

- Siemens Sinamics V20

- Do-More Designer

- C-more

- BX-DM1E AUTOMATION DIRECT

- EA9-T10WCL Touch Panel

- Remote Access

Start-up