Cast Film Extruder Line Controls Upgrade

Problem

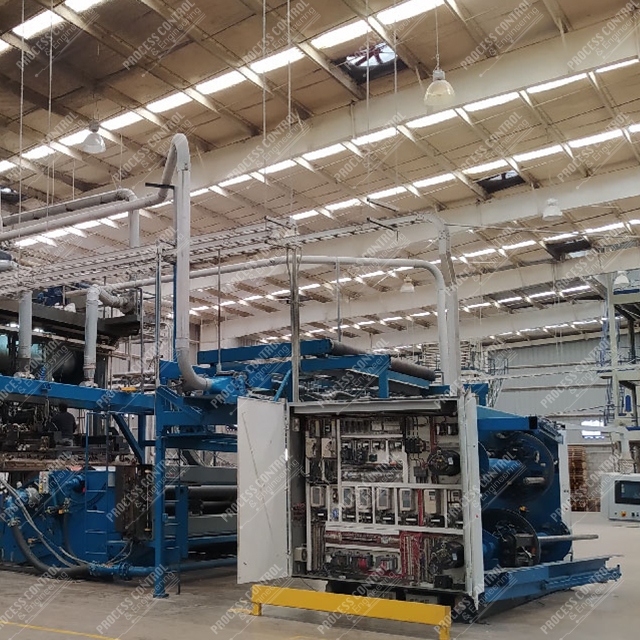

The Customer has a “Cast Film Extrusion Line” that consists of the extrusion of thermoplastic polymers. To achieve this, a very precise process is followed and is currently controlled by an old control system that the client wants to upgrade to improve the functionality of the procedure.

Solution

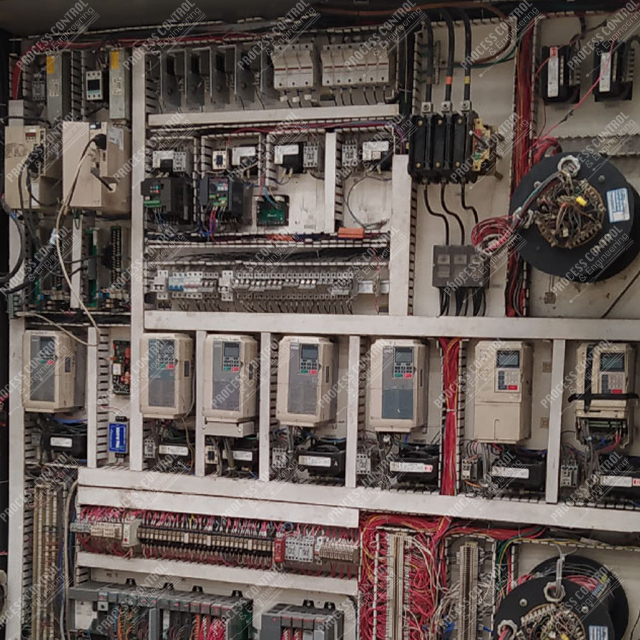

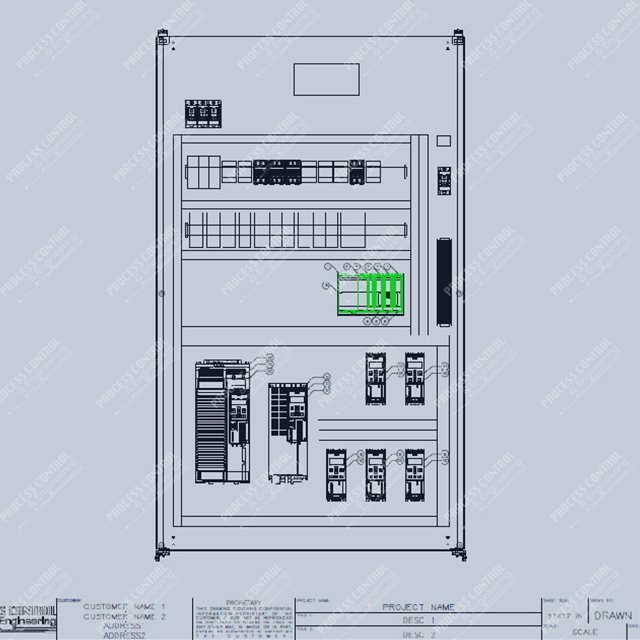

PC&E improved the versatility of the existing process by upgrading the control system of the machine and adding new features. The existing SIEMENS PLC controller was upgraded with its correspondent expansion and remote I/O modules. A new SIEMENS Comfort Panel HMI was provided as well. All the AC and DC drives were changed and incorporated into the SIEMENS PROFINET network. The new PLC and HMI were then connected and communicating through the new PROFINET network.

Duration

About 15 months

Services Provided

- Control Engineering & Design

- Panel Construction

- PLC & HMI Programming

- AC/DC Drives Configuration & Motion Control

- Electrical Installation

- Start-up & Commissioning

Technology Used

- SIEMENS SIMATIC Control Devices

- SIEMENS S7-1500 PLC

- Ethernet/PROFINET Communication

- SINAMICS G120, G120C & S120 Drives

- SIEMENS Comfort Panel

- Safety System

- NDC Gauge System

Start-up