Our Projects

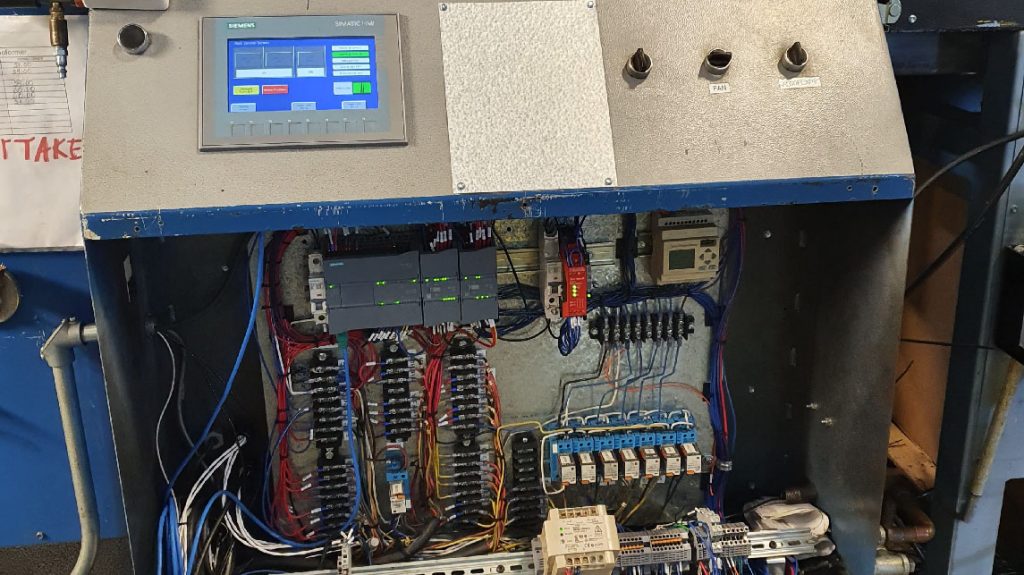

Cast Film Extruder Line Controls Upgrade

A cast Film Extrusion Line had an old control system which the client wanted to upgrade to improve the functionality of the process.

Excess Material Removal Station

The client needs to eliminate the excess material in the manufacture of its parts derived from one of its forging processes by upsetting.

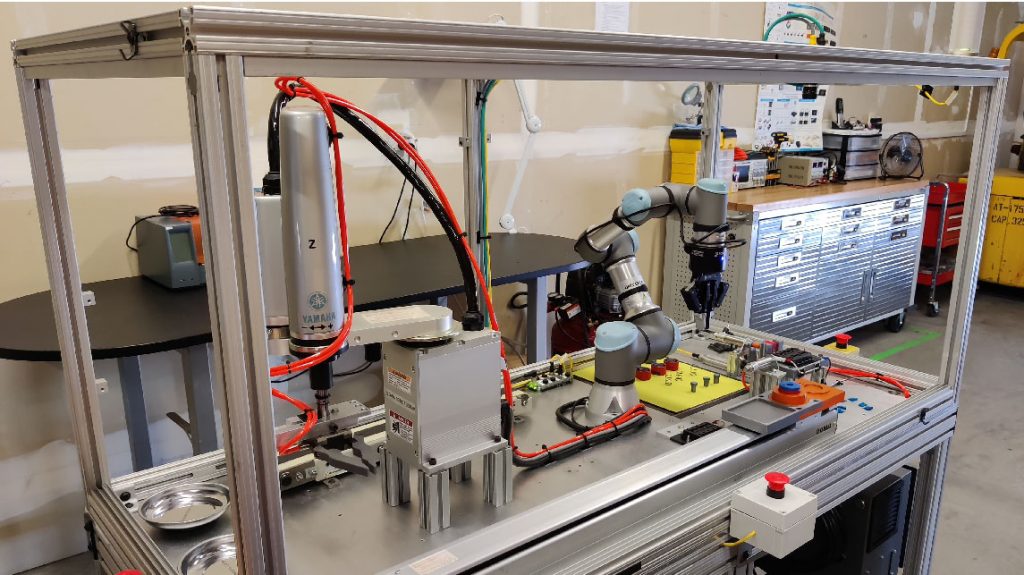

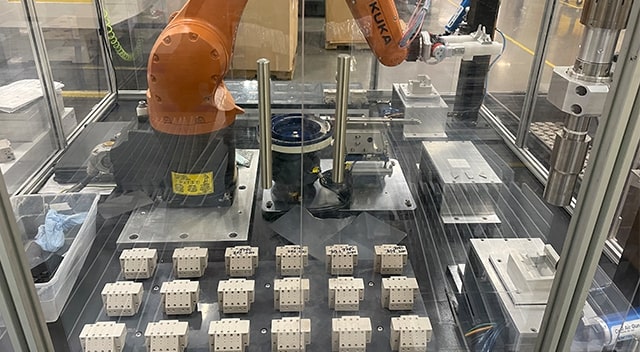

Industry 4.0 Robotic Station

An educational robotic station needed to be updated to represent “Industry 4.0” and provide new additions.

Stacker Safety System

In order to completely protect all the risky zones and possible accident cases is required to implement a second laser scanner in the existing safety system.

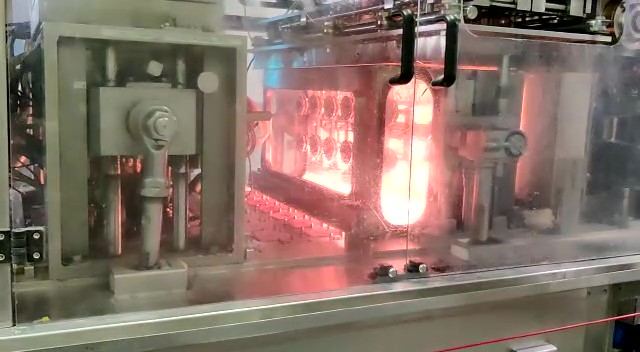

Blue Thermoformer Upgrade

A partially upgrade in a Blue Thermoformer machine is required to increase the system’s capabilities.

CNC Monitoring System

The customer needs a monitoring system for CNC machines to track the activities they perform.

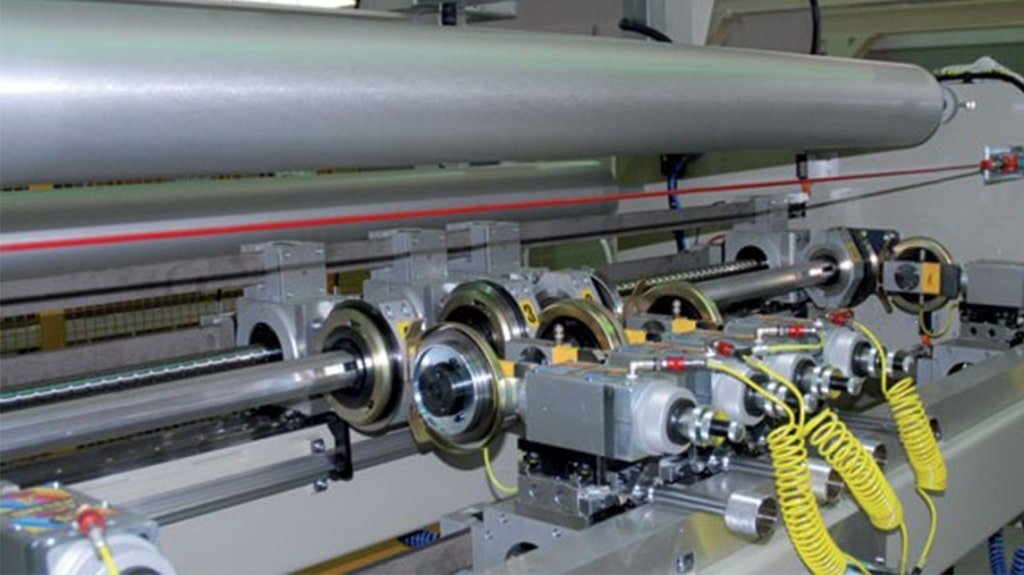

Extruder Winders Siemens Conversion

The customer had an obsolete system, so it was necessary to upgrade the controls of a winder to carry 3 extruders in a single trip.

Robot Weld Seal Liner Safety Installation

The customer required a complete safety system to cover a work area of 4 welding stations, where each station performs a different function.

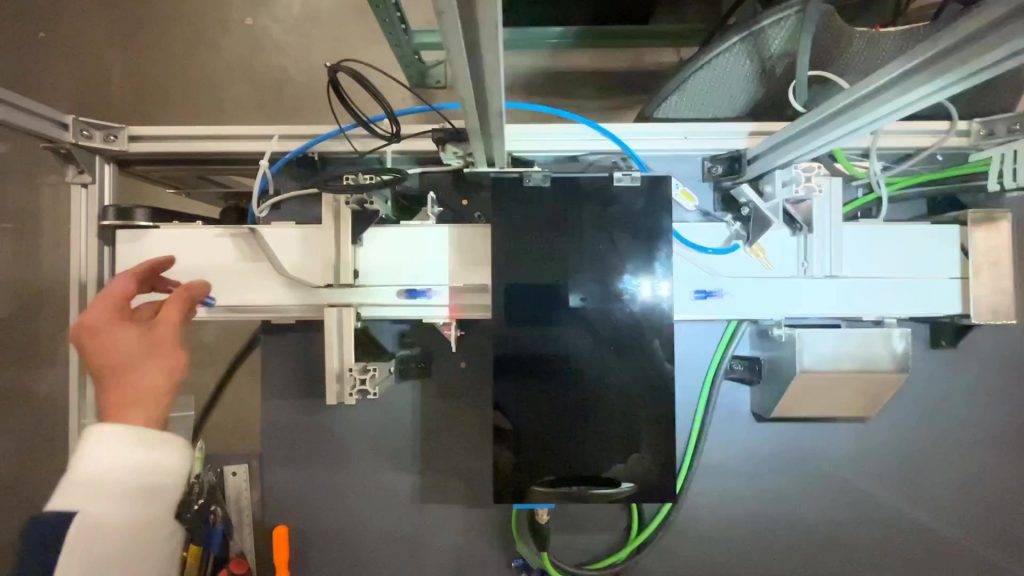

Polytruder Light Curtains

The client has a POLYTRUDER machine which lacked safety measures in the area where the machine was in operation.

Barrel Line PLC Programming

The customer had a plating machine; the plating process was carried out manually, which represented a lower production efficiency.

Ultrasonic Welding Insertion

The client had an ultrasonic welding process that consisted of the insertion of 20 inserts distributed throughout the piece.

Filler Drive System Upgrade

Our customer has a filling line that use a drive system which consists of a Motion controller and 18 Drives.

Vision System on Delta Machine

Our client, an important manufacturer and marketer of medical devices for professional use across a wide field of clinical.

Pin Assembly

Previously operators performed the manual riveting process, so the same process was not always achieved…

3D Printing System

PC&E team designed and implemented a complete and fully automated 3D impression system for printing homes.

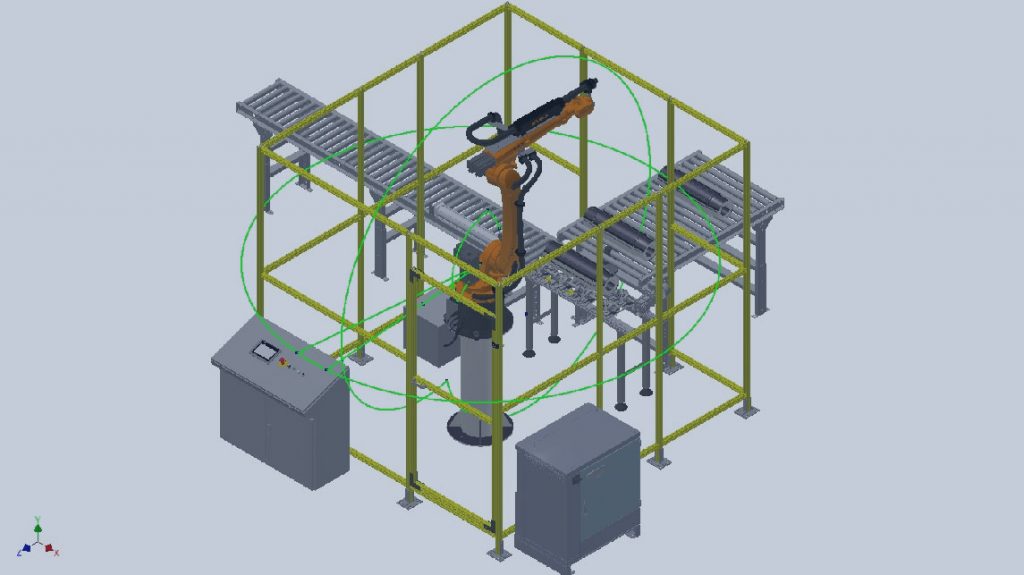

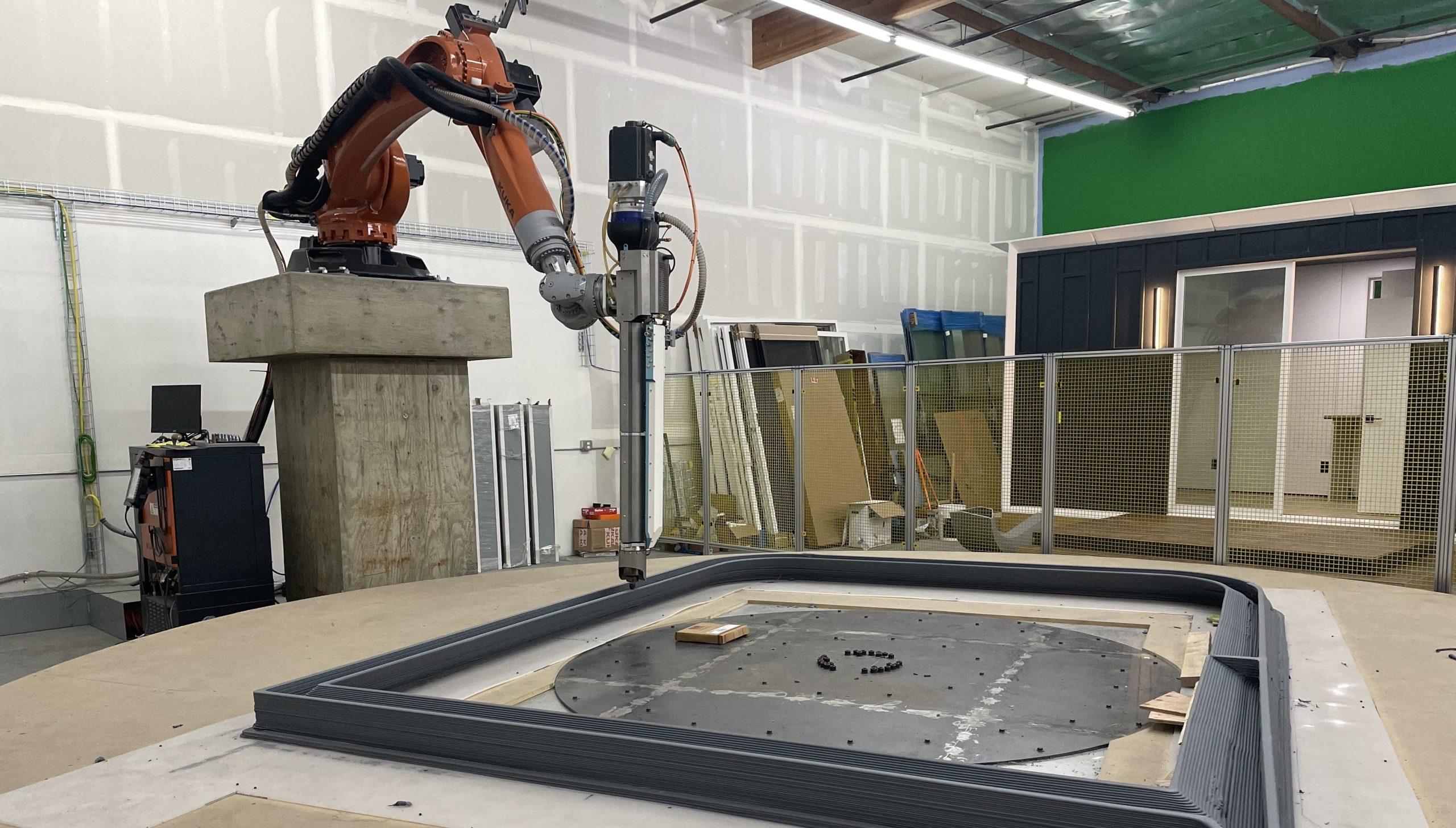

Robotic Milling Cell

Manufacture and installation of a state-of-the-art robotic cell, optimized for machining expanded polystyrene (EPS) blocks in 8 axes.