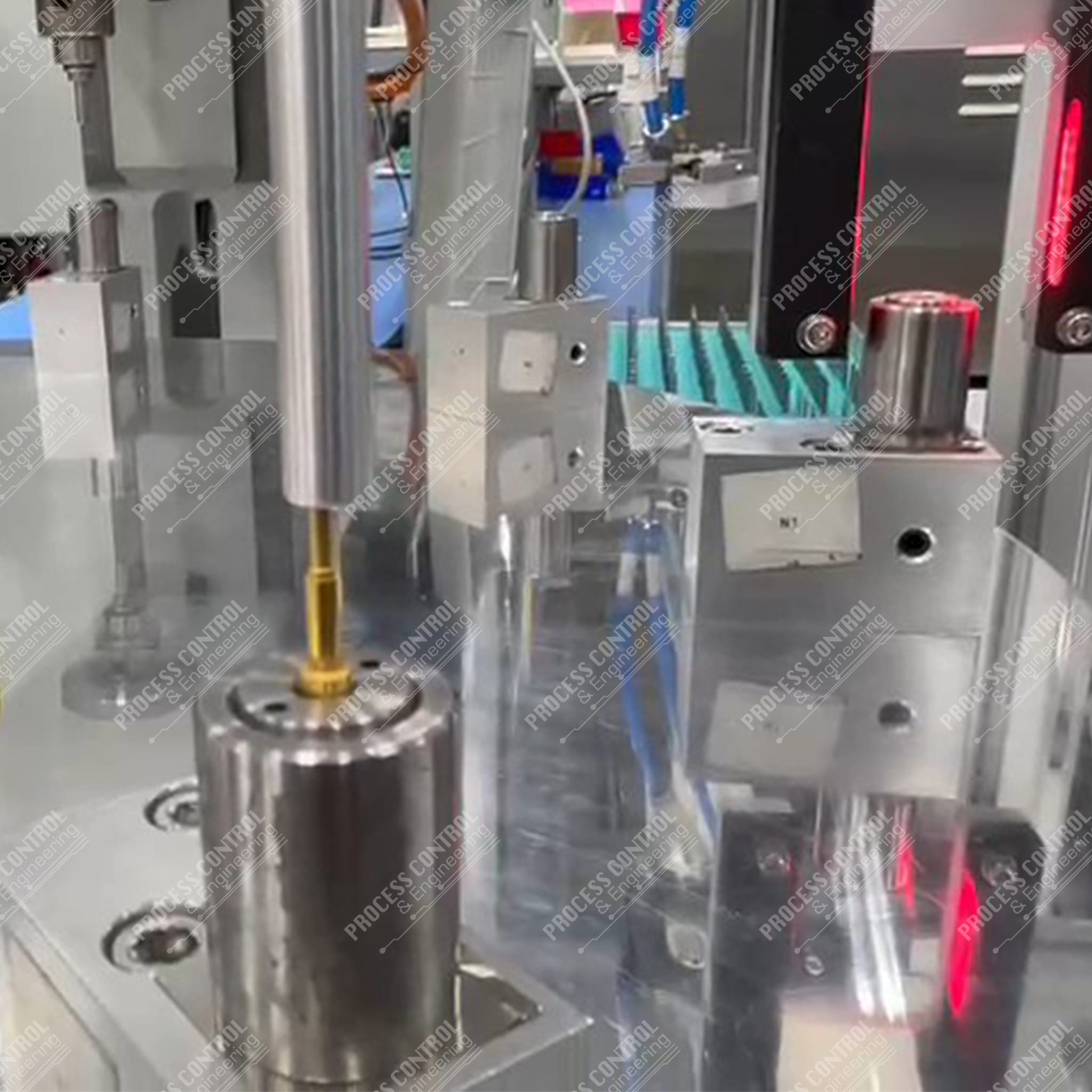

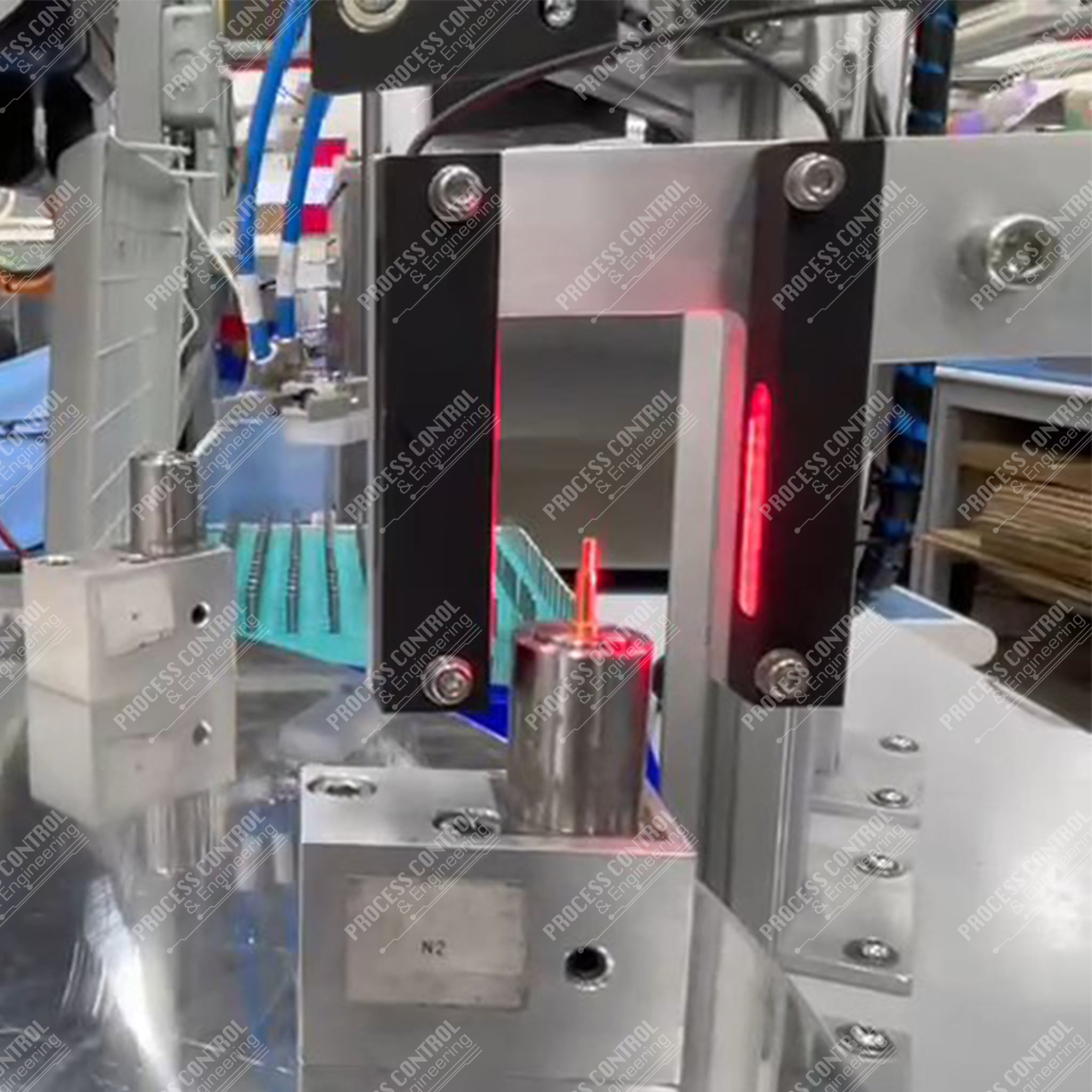

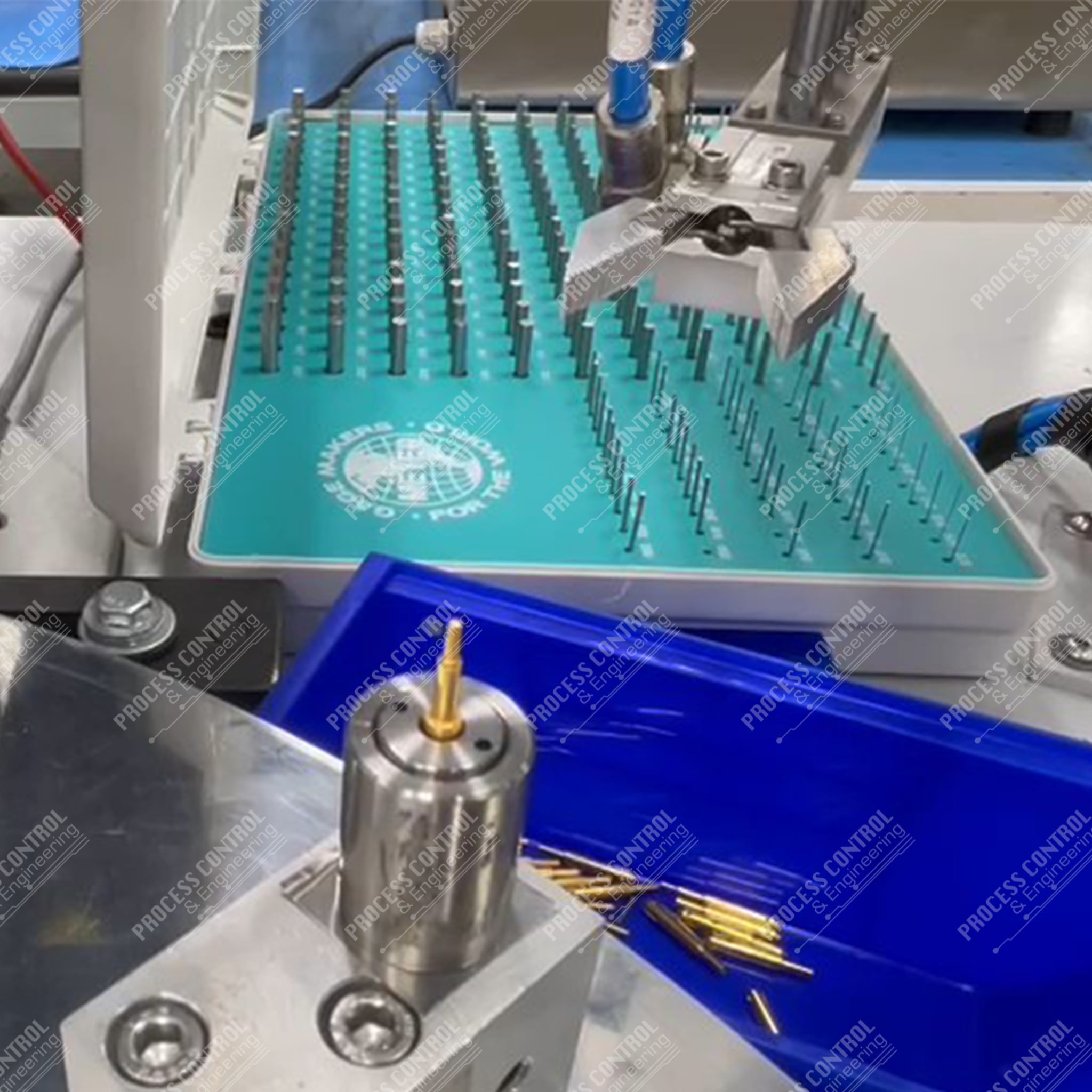

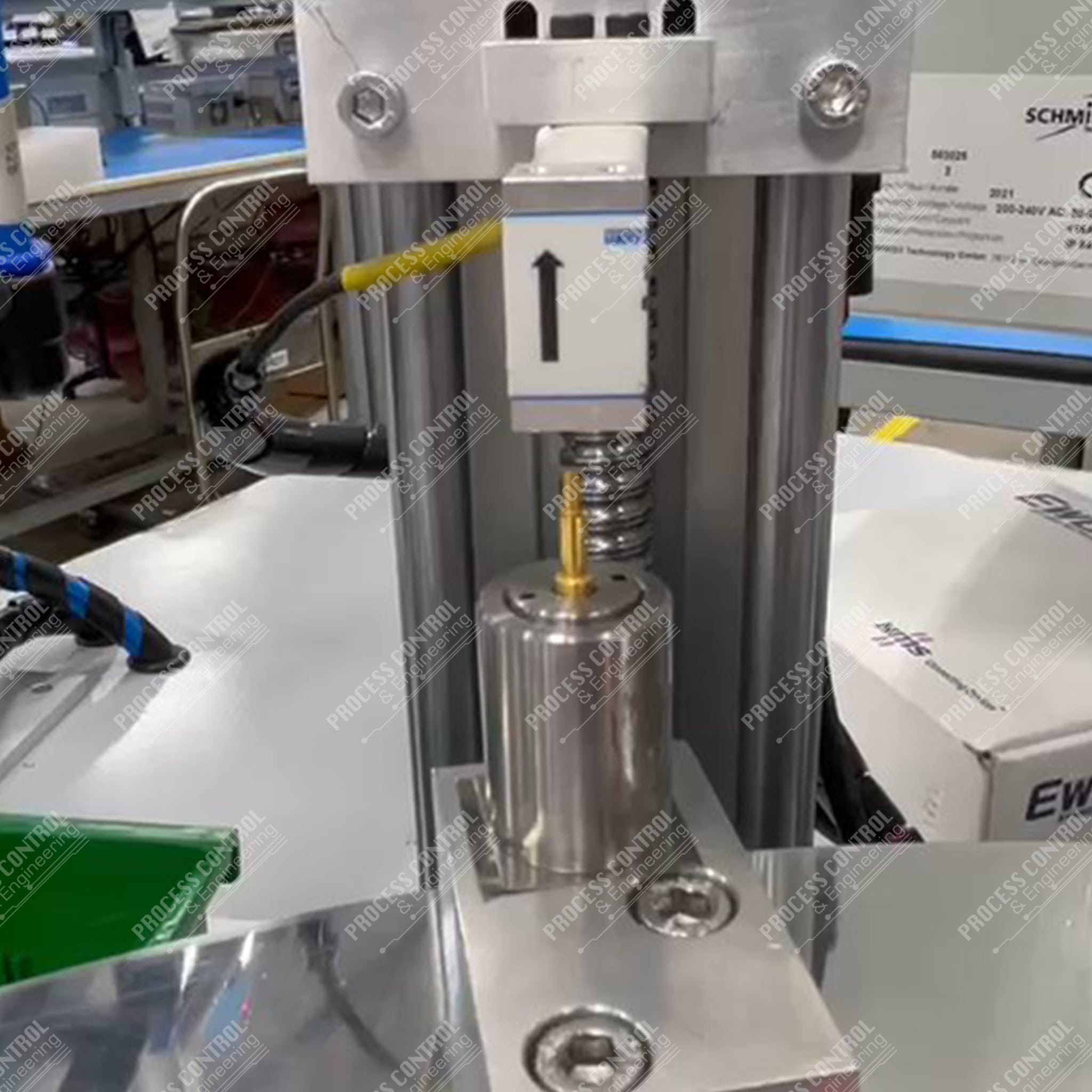

Pin Assembly

Problem

Previously operators performed the manual riveting process, so the same process was not always achieved in all the pins since many of these pins are discarded, that is why the client contacted us to solve the problem and thereby produce a greater number of pins with the same riveting.

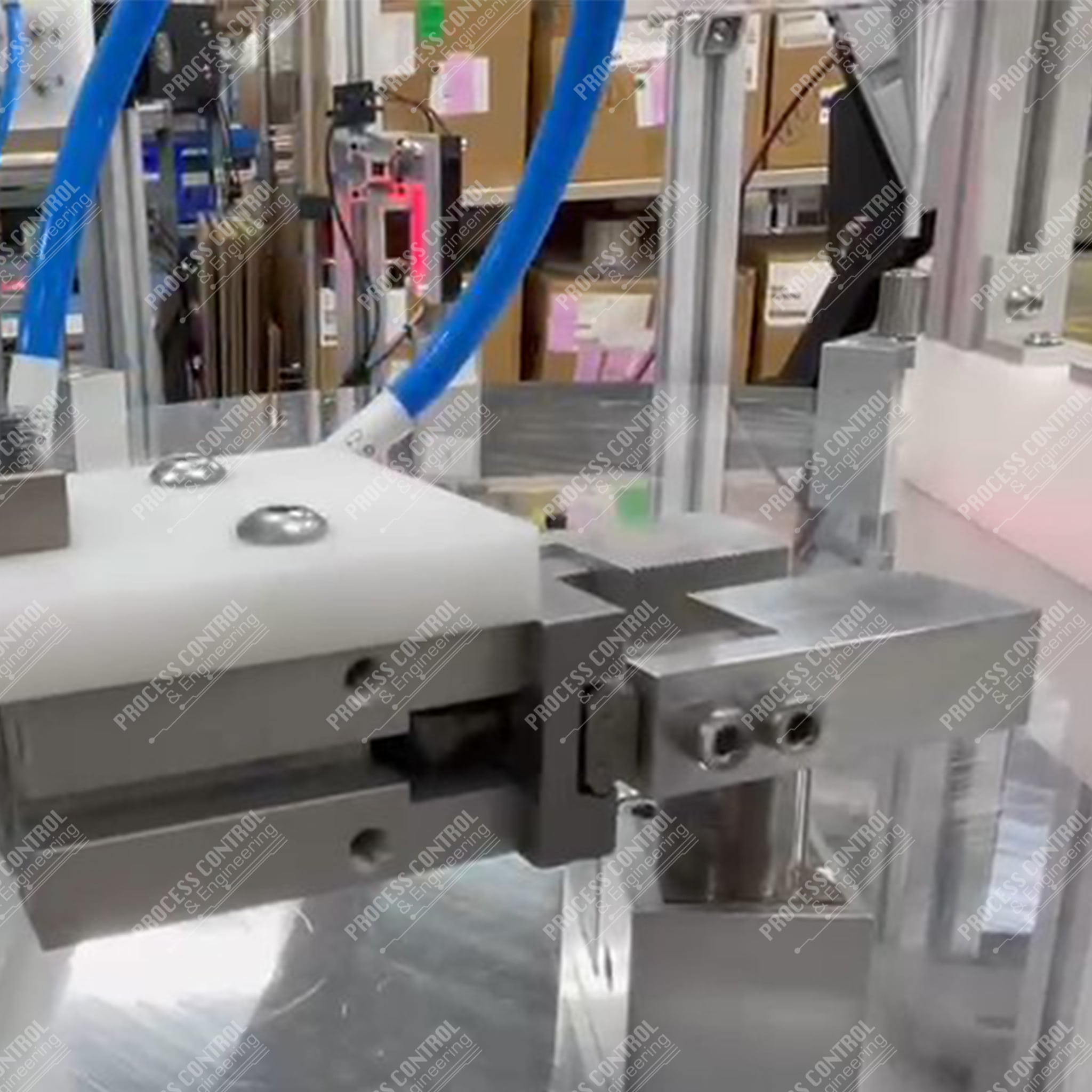

Solution

PC&E corrected the problem by semi-automating the process, placing a rotary table with 8 stations to keep an exact control of the processes for riveting the part, solving the problems presented. Producing up to 1,200 units per day, reducing the personnel to perform the riveting and the number of pieces discarded as a result of human error.

Duration

1460 Hours

Services Provided

- Electrical Design & Schematics

- Mechanical Design

- PLC Programming

Technology Used

- Siemens S7-1200

- BALLUFF Sensors

- FESTO indexer

- Load Cell

Start-up