Ultrasonic Welding Insertion

Problem

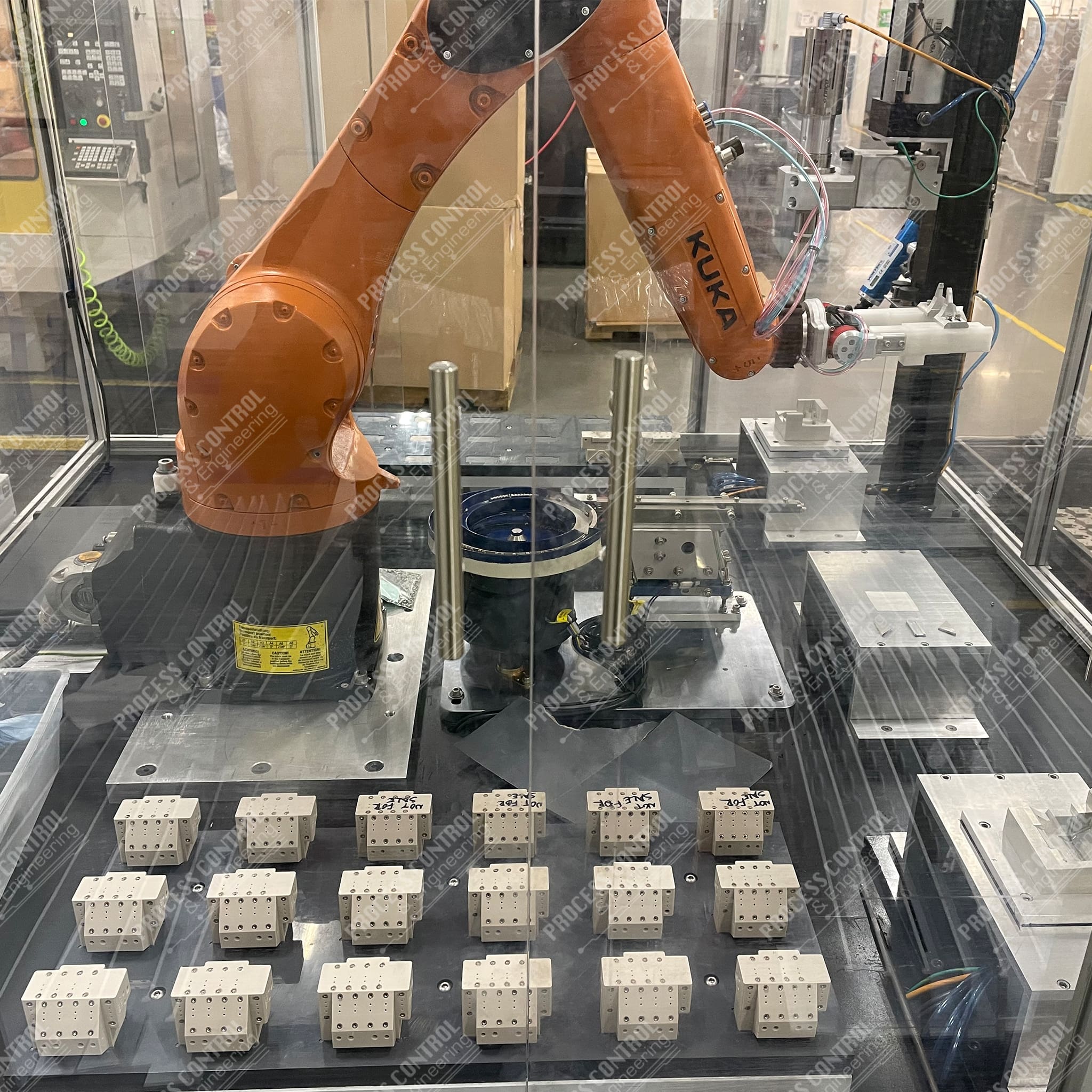

The client had an ultrasonic welding process that consisted of the insertion of 20 inserts distributed throughout the piece, this process was operated manually by a person and the time to make a single piece was approximately 1 hour, so the client needed to automate this process since the manual process did not ensure the quality of the piece.

Solution

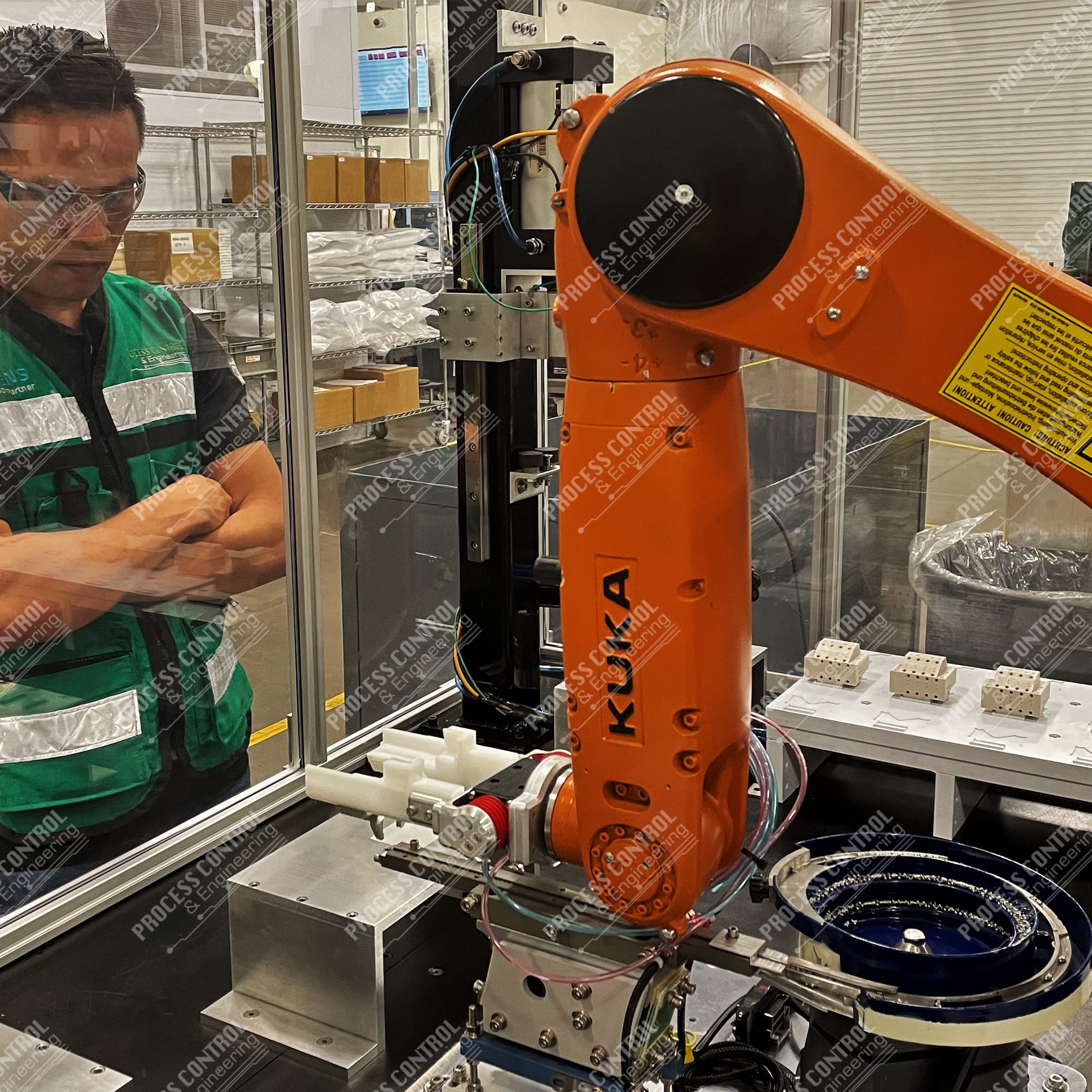

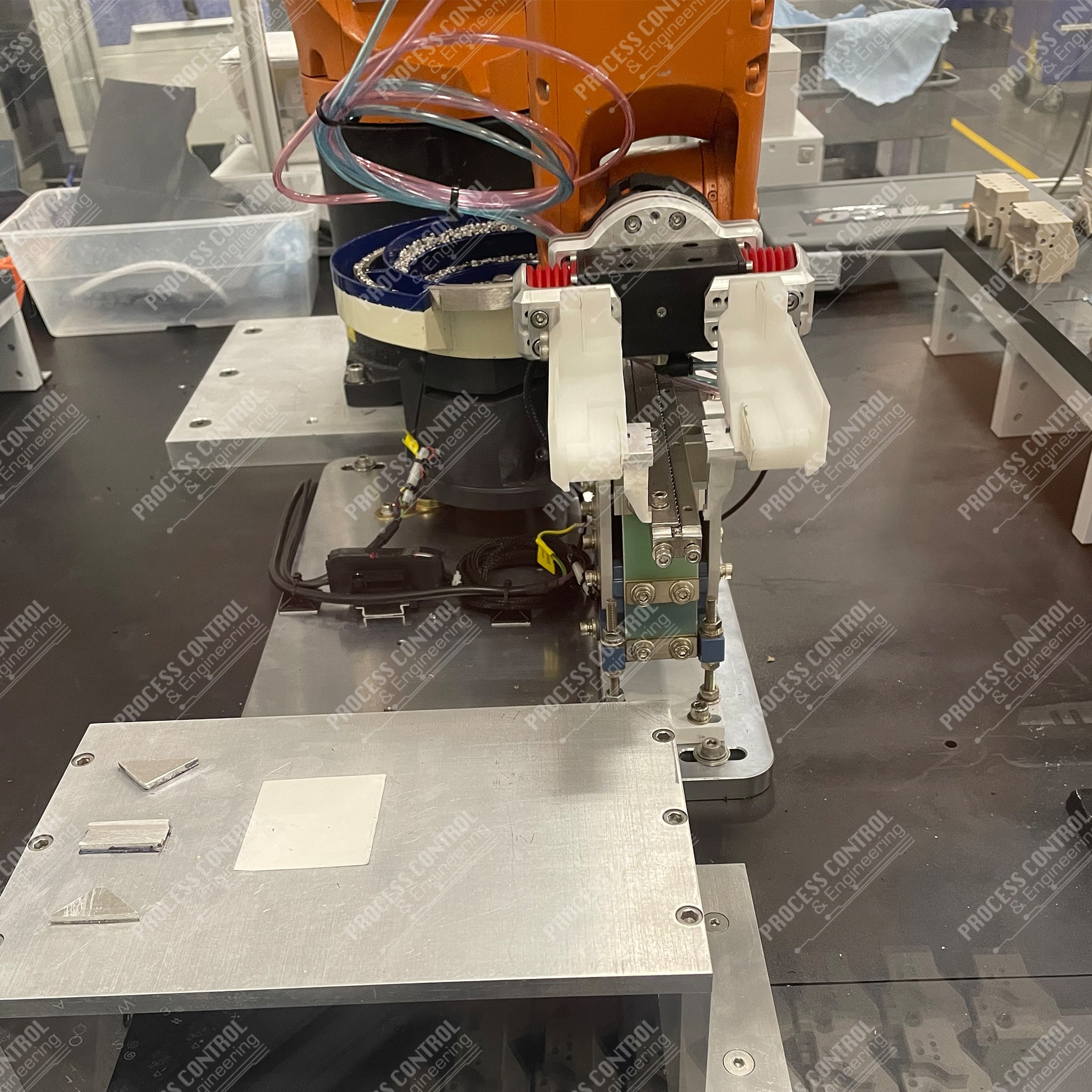

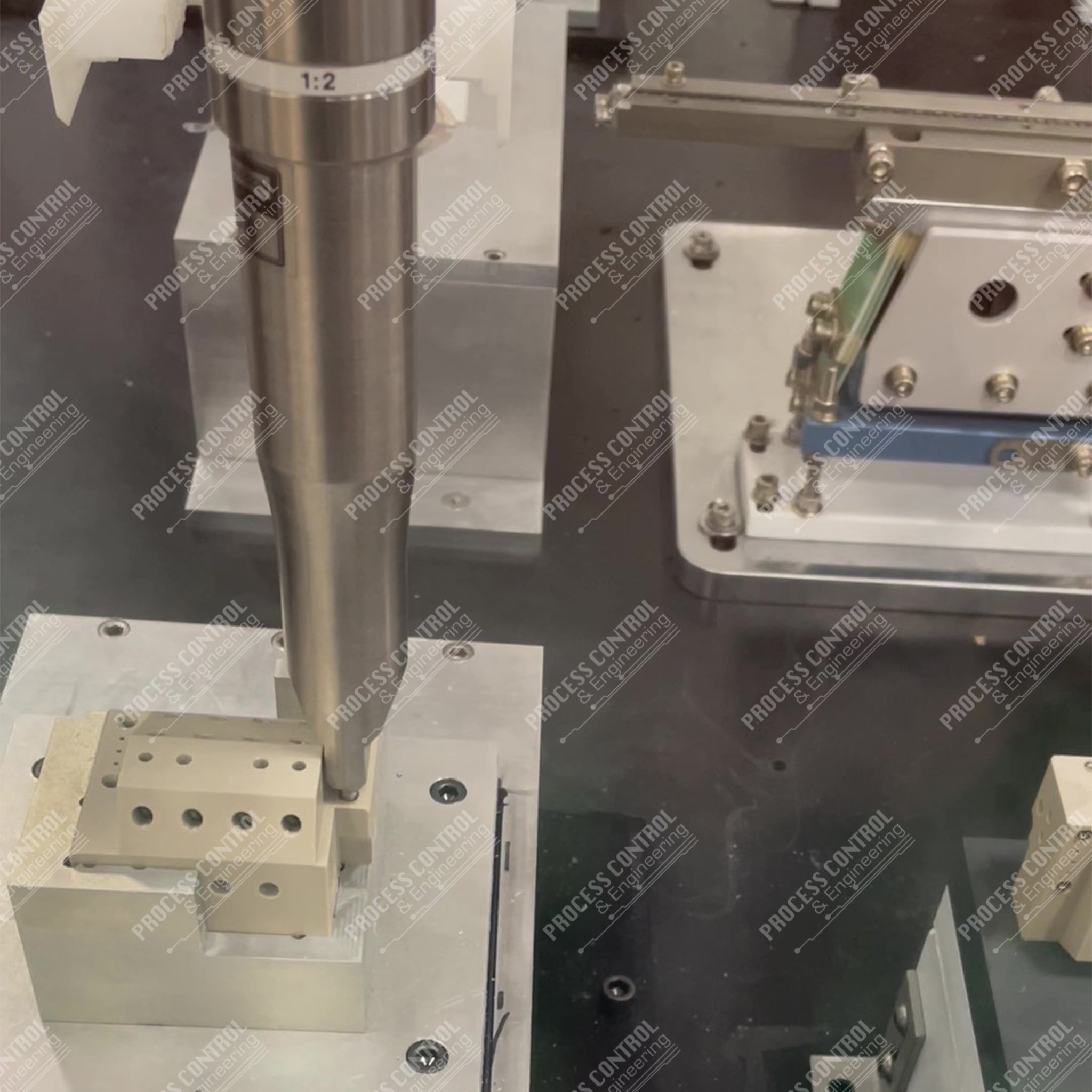

Thinking about minimal human interaction, the PC&E team designed a structure capable of containing 2 welding stations, using a KUKA robot to manipulate and transport the part and inserts around the stations.

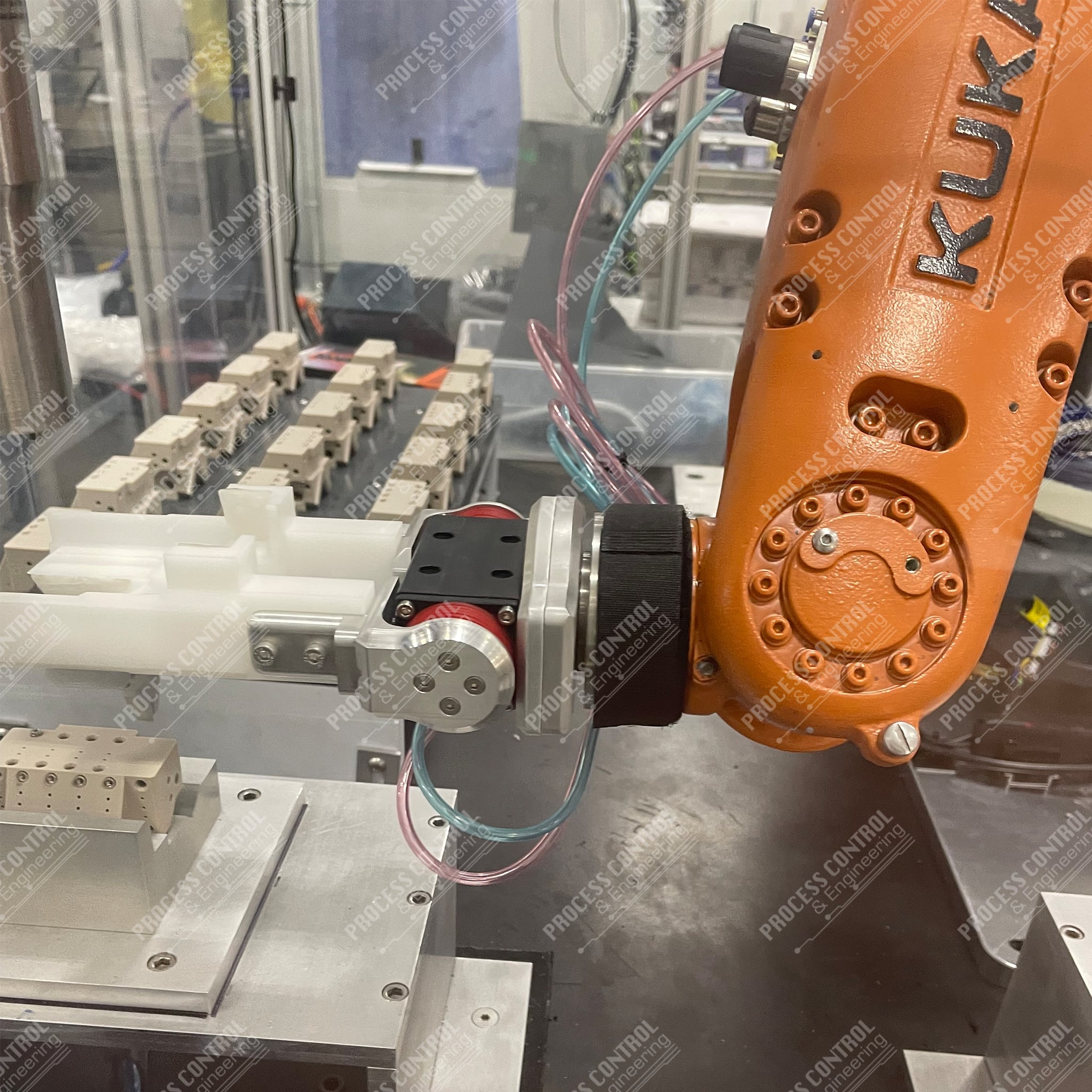

To carry out all these actions, a triple gripper was designed for the robot, capable of holding the piece in different positions, as well as the inserts. In addition to designing custom nests to make it easier to insert the pins.

Currently the station is in operation making 20 pieces per hour, increasing by 2000% the production of the pieces.

Duration

2160 Hours

Services Provided

- PLCs & HMIs Programming

- Robotics & Vision

- Mechanical Design

- Electrical Design & Schematics

- Machine Safety

Technology Used

- Robot KUKA

- Siemens Sinamics

- Rinco Ultrasonic Weldings

Start-up